If your lab works with chemical reagents, especially hazardous chemicals, managing a good inventory isn’t important only for organization and efficiency reasons — it is critical for the health and safety of the personnel. Paper lab notebooks and excel spreadsheets can easily get messy and are prone to human error, which can lead to chemical hazards. A LIMS (Lab Information Management System) is made to assist with laboratory management tasks such as storage and inventory management, labeling, and creating shopping lists. Here’s how you can use a LIMS to improve chemical inventory management in your lab:

1. Decide on a location for each reagent

Ensuring that each item has its own permanent home is the first step to creating an organized environment. If you know where everything belongs and make sure to return stocks to their place after use, you’ll always be able to find what you need, and you’ll avoid gathering clutter in your workspaces.

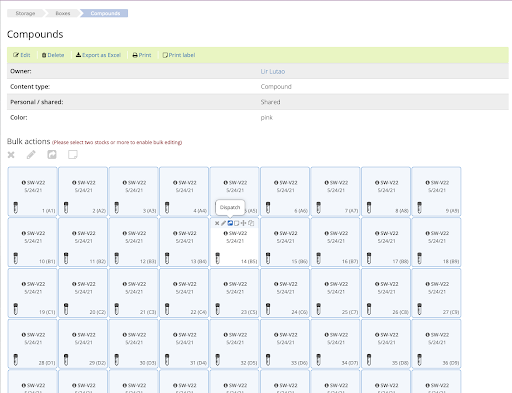

A lab information management system can be used to set a location for each reagent, from storage rooms, through fridges and cupboards, and down to the level of specific boxes and containers. This layered system lets you look up any reagent you need and find it without trouble.

When dealing with chemical compounds, choosing locations carefully is necessary to prevent hazards. Here are a few things to take into account when deciding on locations:

- Chemical compatibility: use a chemical compatibility chart to sort all chemicals into compatibility groups. Store incompatible chemicals at least 3 meters apart, and at least 5 meters apart if there is a risk of a violent reaction. Print a chemical compatibility chart and post it in the lab and next to chemical storage cabinets and fridges to make sure nobody forgets this information.

- External factors: avoid exposing chemicals to heat or direct sun — this may lead to degradation of containers as well as degradation of the chemicals themselves. Avoid storing chemicals in moist places such as under the sink.

- Avoid storing chemicals on countertops, in fume hoods where people work, or on the floor — in these places, they can be easily knocked over. Chemicals should have their own dedicated storage spaces.

- Flammable materials should be stored in certified laboratory-safe and explosion-proof refrigerators.

- To contain possible leakage, liquids should be stored in chemical-resistant trays

- Storage areas must be properly ventilated.

2. Track orders and usage

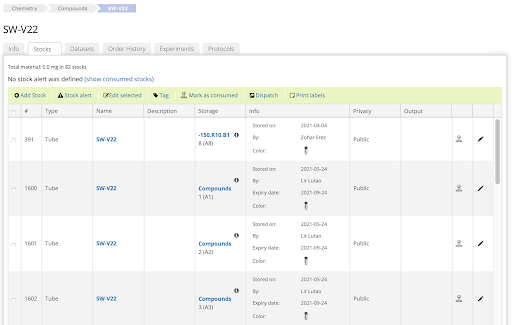

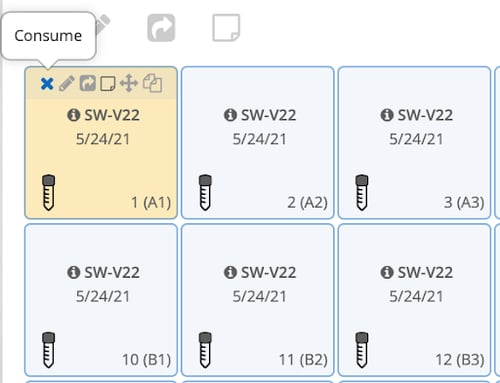

It’s important to avoid stockpiling chemicals because large quantities can pose a serious chemical hazard to the lab personnel. To ensure that you don’t order more than necessary, keep track of your remaining quantities in your lab information management system. Record all the orders you receive and whenever you use up a container mark it as consumed. A good LIMS system will offer the option to send you notifications when stocks are running low, so that you only order new ones when you really need them. Keeping track of quantities will also give you a clearer image of how much of everything you use on average, and how long it takes you to go through the ordered amount, so you’ll be able to make calculated orders.

Keeping track of your stocks will also help you ensure chemical storage rotation and avoid hazards caused by chemical deterioration. Write down expiration dates in your lab information management system and not just on the container itself. You’ll receive a notification when the reagent expires, and won’t end up forgetting about it and letting it deteriorate. If you notice that you don’t manage to use up a stock before it expires, you’ll know to order less next time.

3. Make sure to label everything properly

In order to identify the contents of the container and warn of hazards, reagents should be labeled according to regulatory requirements. The labels should include:

- Contents

- Date opened

- Significant hazards

- In case of hazardous substances: directions for use, first aid, and emergency procedures

Make sure that if the contents of a container change, or if new information is added regarding the handling of the reagent, you update the label accordingly.

If the label of a container is lost, the container should be marked to let personnel know that it’s an unknown substance, for example, “CAUTION: UNKNOWN SUBSTANCE, DO NOT USE.” The container should be stored in isolation until the contents can be identified, or disposed of according to regulations.

You can use your LIMS to design a consistent labeling system with pre-made or custom fields. This will make your storage more organized and help you avoid human errors such as wrong information or incomprehensible handwriting.

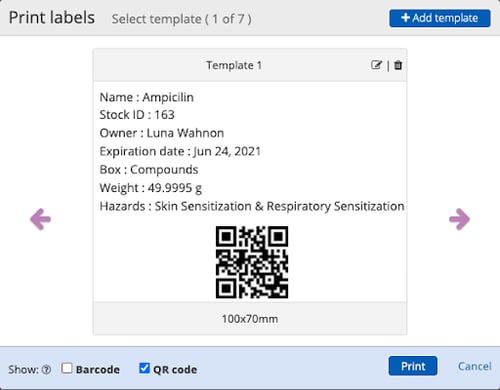

Look for a LIMS system that offers QR-code or barcode labels, which can be scanned to add a compound to an experiment entry to keep all information tied together. Knowing exactly when and where was each reagent used will help create reproducibility of experiments and achieve a fuller, more accurate record of research.

Labguru Lab Information Management System for Chemistry

Labguru is an all-in-one research software for chemistry laboratories, integrating compound management, experiments, protocols, and informatics software for data analysis and processing.

Labguru helps you with chemical inventory management using the storage and inventory modules that enable you to assign locations to reagents, track every single box and vial, record quantities remaining and expiration dates, create shopping lists, and print QR or barcode labels. Every compound can be linked to experiments and projects, keeping all your data tied together in one place and preventing information silos.

To learn more about Labguru for chemistry labs, click below -

%20(4).png)